How trusses work

A truss is made up of multiple triangular units, and each triangle helps manage both compression and tension forces. This combination spreads the load evenly across the structure, giving it remarkable strength without weighing it down like a sumo wrestler at a ballet recital.

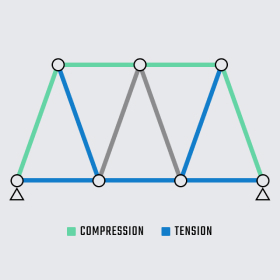

Compression forces affect the vertical and diagonal components of the truss.

Tension forces hit the horizontal parts, particularly the bottom beam (our unsung hero).

It’s the triangular shape that makes trusses so strong. Triangles are basically the superheroes of geometry – their angles and sides can’t change without seriously stretching something, which makes them highly resistant to deformation under pressure.